Professional installation techniques for false ceilings and false walls

December 15, 2025

Keywords:

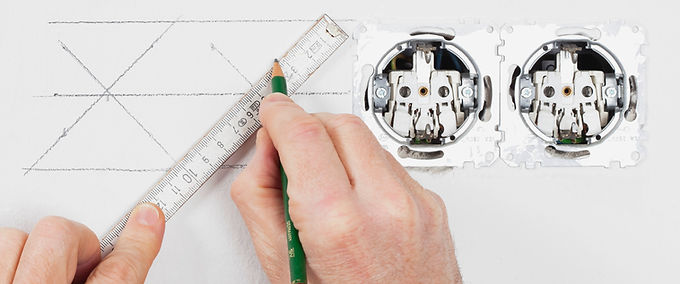

Installation begins with marking the guidelines on the walls and ceiling. Laser levels, tracing lines, and repeated measurements allow us to mark the exact height of the suspended ceiling and the overall dimensions of the false walls. At this point, the perimeter guides are attached and, in the case of a suspended ceiling, the hangers that will support the main framework are installed.

The metal structure represents the skeleton of the entire system. The profiles are cut and assembled according to the manufacturer's recommended spacing and layout, based on the weight of the panels, the clearance between supports, and the required performance (for example, fire resistance or sound insulation). In the false walls, uprights and guides are assembled to create a regular grid, which accommodates any necessary wiring and insulation passages.

If the project includes acoustic or thermal insulation , specific panels, such as mineral wool, wood fibers, or other suitable materials, are inserted into the cavities. Their correct installation, without voids or excessive compression, significantly contributes to the final result: an acoustically effective false wall or a suspended ceiling that improves interior comfort.

The panels are then fixed to the structure, screwed in place in a regular pattern, ensuring the panels are aligned correctly and the staggered joints are maintained. For suspended ceilings, the assembly sequence is carefully designed to avoid deformations and to precisely integrate spotlights, vents, inspection hatches, and other technical elements specified in the design.

Once the structure is closed, the joints between the panels are treated with special tapes and fillers, applied in multiple passes and sanded until a uniform surface is achieved. At this stage, any small imperfections are corrected and the substrate is prepared for primers, paints, or other coatings. The quality of the smoothing directly impacts the final appearance, especially in the presence of grazing light or particularly opaque finishes.

Professional installation also pays attention to details : connections with existing walls, closures on pillars, edges of cornices, niches, and light openings. Tightly drawn cornices, clean edges, and surfaces that aren't warped are the result of proper construction and a patiently executed finish. When all these steps are followed, the suspended ceiling and false wall appear to be original architectural elements, not artificial additions.

Highlight

• Well-designed metal structures ensure flatness and reduce movement and cracking.

• The correct arrangement of suspensions, uprights and guides improves acoustic and stability performance.

• Joints well treated with specific tapes and fillers make the lines between the panels invisible after painting.

• They allow for the clean integration of spotlights, inspection hatches, grilles and technical tracks.

Low Light

• Overly spaced struts or undersized suspension can lead to buckling and cracking.

• Improperly taped or sanded joints emerge in grazing light, ruining the final effect.

• Errors in the position of the reinforcements make it difficult to subsequently fix wall units, shelves or heavy elements.